In the process of manufacturing various home-made products, fixtures and structures made of metal, it is often necessary to weld two workpieces at an angle of 90 or 45 degrees. It is easiest to do this with the help of improvised means, especially if you need to perform large volumes of welding work.

To quickly set mating parts as accurately as possible at a given angle, you can make a simple universal square for welding with your own hands - and for this, trimming profile rectangular pipes with side dimensions of 40x20 mm are perfect.

In addition, ordinary pieces of metal, as well as bolts with nuts for connecting steel plates, will be required. To make such a useful fixture for the home workshop is very simple - you will need a grinder, a drilling machine or an electric drill, as well as an inverter-type welding machine or a semiautomatic device from the tool.

The main stages of work

Using a grinder with a cutting disc we cut off two pieces of a 40x20 mm profile, with one side being at an angle of 45 degrees. Using an ordinary construction square, we expose two workpieces at a right angle and weld.

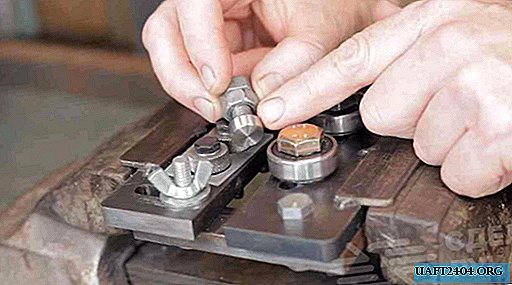

At the next stage, we cut out two plates and two "ears" from a suitable piece of metal in which holes for fasteners (bolts with nuts) must be drilled. To the inside of the homemade square we weld first the “ears”, and then two steel plates.

Two nuts are welded to one of the plates - for rigid fixation of the welding angle at an angle of 90 or 45 degrees with a bolt. The welding spots must be cleaned with a grinder by installing a grinding or grinding wheel on it.