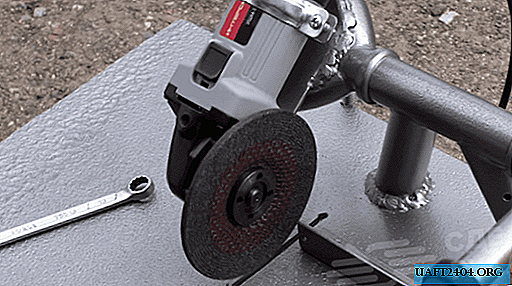

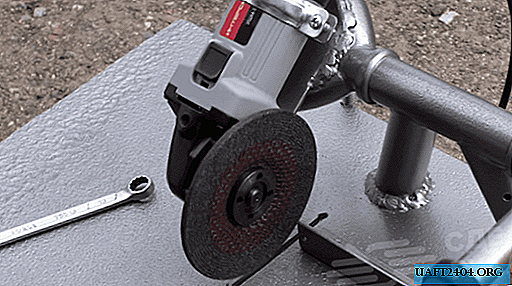

If it is not possible to buy a factory cutting machine for metal, then it can be made without problems on your own, taking as a basis a small grinder. The mount for the angle grinder itself can be made from improvised materials. For example, from a bicycle frame, which will act as the main element of this makeshift design.

In addition to the bicycle frame, other materials will also be required - for the manufacture of the table on which the metal cutting machine will be placed. If you have such a table, then it remains only to make a mount for the grinder. To do this, we will use the frame trim from the old bike.

The main stages of work

First of all, remove the steering wheel and cut off a small piece from it, which is perfect for this homemade product - it will serve as a handle. In principle, a piece of steel pipe of suitable diameter can also be used for this. From the front of the bicycle frame (from the side of the fork) we cut a piece 100 mm wide.

Further, it is advisable to immediately replace or lubricate the bearings. Also, using a file, we remove the burrs and level the surface in the place of the cut. The result should be a simple workpiece with even parallels.

Then you need to slightly shorten the plug itself - the size of the grinder. After that, we proceed to the assembly of the main unit. Next, from a piece of plate we make a “sole” for angle grinders, which is attached to the bicycle fork.

At the last stage of work, if there is no table, then it will be necessary to make a bed with a countertop (it is best to use 6 mm thick sheet metal for this). If the workshop has a suitable workbench or table, then simply weld the assembled structure to them.

The detailed process of manufacturing and assembling a home-made cutting machine for metal can be seen in the video on the website.