A simple adjustable clamp can be made from a profile pipe and an eccentric clamp-clamp. It is intended for fixing and gluing wooden blanks in the garage and home workshop.

First of all, it is necessary to cut a piece of a profile pipe of rectangular cross section suitable for the length (size - 40 * 20 mm). You will also need to cut 4 more pieces of steel strip or plate.

From the segments of the plates, it is necessary to weld the “boxes” according to the size of the profile pipe. However, between the walls of the profile and the segments of the plate, you need to put a piece of paper so that there is a gap.

The main stages of work

At the next stage, it is necessary to weld the workpiece from the profile pipe perpendicularly to the resulting duct. For greater convenience, you can use the magnetic corner.

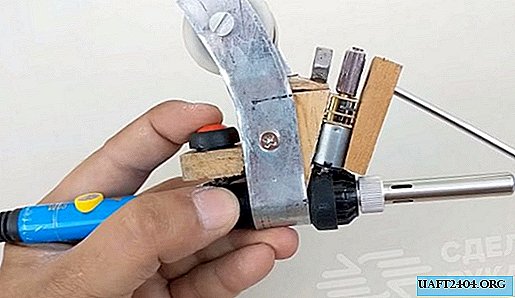

Next, the master welds the plug from a piece of the plate to the end of the profile pipe. An eccentric clamp-clamp is then welded to it. First, you will need to trim part of the device with a grinder.

To the moving part (a box of pieces of plates) you need to weld a nut into which the bolt is screwed. Before this, the author drills a hole of the desired diameter in the workpiece.

After that, you can start painting all the parts and assembling the device. For details on how to make an adjustable clamp for fixing and gluing wooden blanks, see the video on our website.