If you need a practical and functional grinding machine for processing wooden workpieces, which does not take up much space in the workshop or garage and at the same time costs much cheaper than factory analogues, then there is only one way out - to make such a machine with your own hands.

Materials for work

For the manufacture of a home-made grinding machine for wood, affordable and inexpensive materials will be used, so this home-made can be attributed to the budget class.

So, to work, you need a profile pipe 20x20 mm with a wall thickness of 1.5 mm, a sheet of plywood 15 mm thick, a piece of steel water pipe with an inner diameter of 50 mm, a bearing 20x47 and a piece of studs with a diameter of 20 mm.

To reduce engine speed, you can use several options at your discretion - a regular pulley with a belt drive or gears of the required diameter, which can be removed from the gearbox.

The drive from the washing machine will be a 420 W automatic machine (but in this case a 300 W electric motor will do).

Manufacturing process

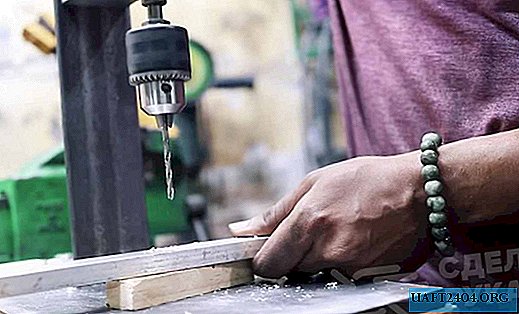

We cut the profile pipe into segments of the required length, and then weld from them two rectangular frames for the frame. Then we make a mount for the shaft and belt pulley, and a "seat" for the electric motor from the washing machine.

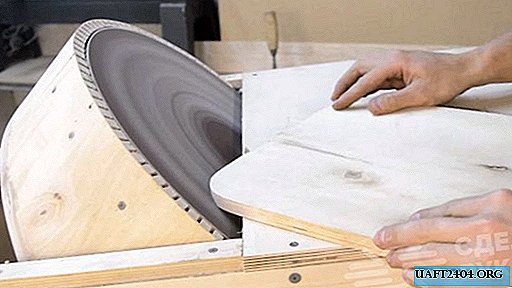

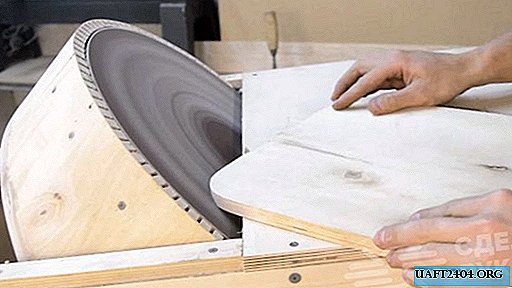

Next, we make a round disk from plywood, glue sandpaper on it (on double-sided tape), and also fasten a long hairpin with bolts that will adjust the angle of inclination of the grinding wheel. After that, we make a protective casing for the disk and sheathe the frame with plywood.

In this way - from practical materials you can make a practical and functional grinding machine for wood for a garage or home workshop. See the video for details.