Trapezoidal interchangeable blades are used in special knives, which are designed for cutting and precise cutting of textile and office products, as well as building materials (for example, when cutting carpet, linoleum or paper wallpaper).

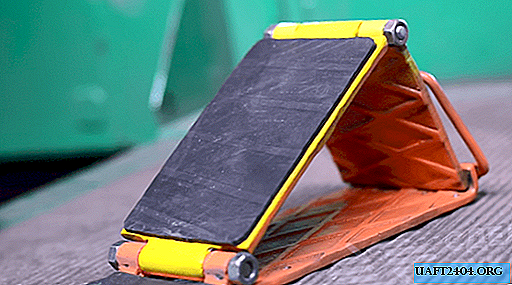

At the same time, the blades are universal - they can be used for non-standard tasks, and are also suitable for installation in different hand tools or on makeshift devices and machines. In this article, we will consider how to make an enlarged copy of an interchangeable trapezoidal blade for DIY construction knives.

The main stages of work

To begin with, from a wide metal plate (it is desirable to use alloy tool steel) we cut a trapezoidal workpiece of suitable size. Then we process the ends on a belt grinder, maintaining a certain angle of the sides.

After that, we mark the surface of the workpiece, core and drill two holes on the drilling machine. Using a manual jigsaw or on a band saw, we expand these holes, making small slots that are needed to fix the blade in the construction knife.

At the next stage, we perform bilateral sharpening of the cutting edge of the blade on the grinding or grinding machine. Then the cutting edge of the blade must be hardened - for this we heat the plate red-hot and cool in a metal container with water.

After the “water procedures” we send the blade for a while to the oven for “drying”. At the end, we perform the final sharpening of the cutting edge. The detailed process of making a knife in the form of a blade, see the video on the site.