Unlike traditional bayonet and shovel shovels, this tool has a somewhat non-standard appearance - the blade is located at an angle of 45 degrees relative to the holder. Thus, using such a homemade shovel, you can not only dig the earth, but also perform other operations - for example, tamping the soil or cutting grass.

Stainless steel is used as the main material for the manufacture of a universal shovel-chopper. You will also need a metal nozzle for attaching the handle and three thick steel rivets. If there is no stainless steel at hand, then a piece of any sheet steel with a thickness of about 2-3 mm is suitable.

The main stages of work

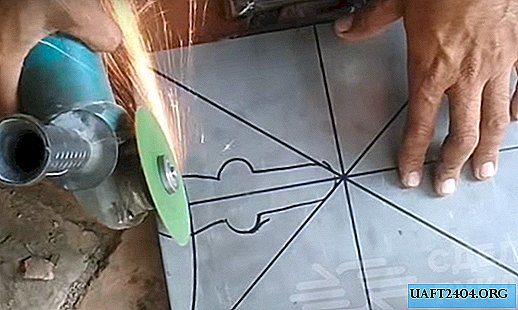

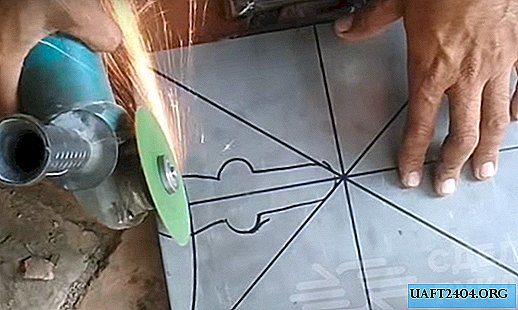

From a sheet of stainless steel we cut a piece of a rectangular shape of the size you need. We mark the surface, and on one side we make a semicircular cutout with a grinder. Then we roll the sheet on a bending machine to give the workpiece a concave shape. Next, you need to make markings for attaching the nozzle under a wooden holder.

The edges of the sheet are treated with a grinder to remove burrs. After this, it is necessary to fix the nozzle for the rivets on the rivets, after drilling three holes. At the last stage of work, using a grinder, it is necessary to slightly round the quack and make a small cutting edge to better bite into the ground.

If desired, the surface of the shovel can be polished from the inside and outside. But there is no particular need for this. For the step-by-step process of manufacturing a universal shovel-chopper for a garden and a garden, see the video on the website.