This homemade product is compact in size, so it is useful in any workshop - thanks to the universal sizes of the platforms of some power tools, this device can be used in the process of working with a manual circular or milling cutter. As a basis for a homemade platform with a sled, a 20 mm thick plywood sheet is suitable.

The main stages of work

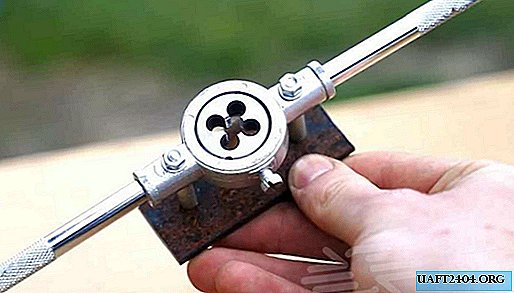

The first thing we do is cut out a piece of plywood from a sheet of rectangular shape of suitable sizes, which are determined individually. We make a marking under the guide and select the groove with a manual milling cutter. Then we install a metal plate "with sides" and fix it for reliability with self-tapping screws.

At the next stage, we take two wooden blocks of 50x100 mm, clamp them in a vice and make a wide groove of a rectangular shape. We glue these bars along the edges of the plywood, and on the reverse side we fasten with screws.

Install the slide

Next, you need to cut the metal guide in half, drill holes in them and fasten the two halves to the bars - these will be adjustable slides for a circular saw, milling cutter, and also another power tool with universal supporting platforms.

From a short wooden bar, it is necessary to emphasize with a latch, which is attached to the lower metal guide, and is needed to cut the workpieces at an angle of 45 degrees. If desired, a plywood platform with a sled can be painted. See all stages of work in the video on the site.