When there is a need to make something of metal bars with your own hands, doing cold forging, then you can not do without a special fork. And it’s not at all necessary to buy this accessory.

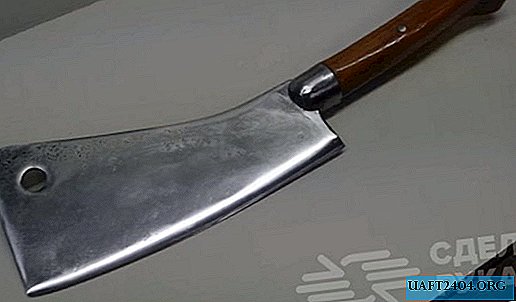

The plug can be made from various materials at hand, but if you have an extra or broken ring wrench, then it will be the best for this purpose, since it takes a minimum of effort to transform it into the right tool.

To work, you will need: in fact, the cap wrench itself or its fragment (with the surviving curved part), a marker, a vice, a hammer, a grinder, an electric drill, a welding machine. Please note that the spanner itself must be made of durable material.

The main stages of work

To begin with, we cut off the part intended for putting it on the nut at the folding key so that the product takes the form of the letter “G”. But at the same time we leave small edges of the cut "round". Grind the sharp parts, round off a bit.

Marker in the middle with a marker, mark a short bend with the letter "T" (the upper "crossbar" is from the end, it is wide) and cut out the holes with a grinder, holding the key in a vice. It remains only to extend the handle of the future fork. To do this, insert it into a metal pipe and scald.

Choose the length of the pipe as you wish. You can give the product a more aesthetic appearance by wrapping it with insulating tape.

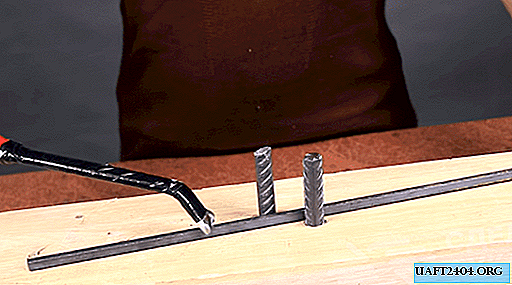

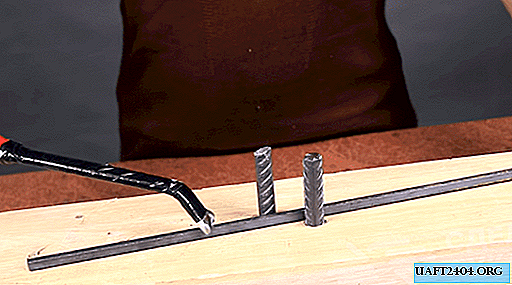

To start working with the manufactured tool, we take two pieces of reinforcement, sharpen them from one edge, drill two holes at a distance of 5-7 centimeters in a massive board and hammer the pins into them. Now everything is ready for the creative process, you can begin! The plug turned out to be comfortable, durable and light.