If an old manual jack is lying around in the garage, in the country house or in the home workshop, which you will no longer use for its intended purpose, do not throw it in scrap metal. It will make a simple table vise.

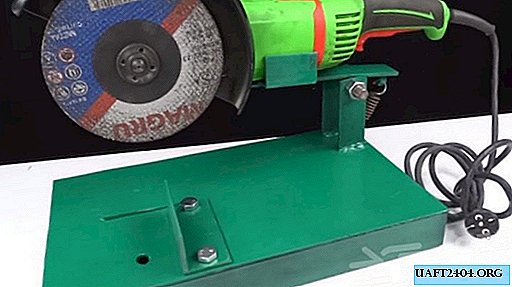

First of all, it is necessary to cut off everything superfluous from the manual jack - it is necessary to leave only those structural elements that will be directly used in the manufacturing process of homemade bench vice.

Next, the master welds the main part of the bench vise from the prepared parts. The screw will be located inside the profile pipe with a groove.

Then you need to weld the movable and fixed jaws of a vice. For this, the master uses two identical pieces of corner.

The main stages of work

Next, with the help of a grinder, it is necessary to make diagonal notches on the jaws of a vice. Moreover, on a movable sponge, it is desirable to make incisions before it is welded. Notches are needed in order to better fix the workpieces made of metal.

At the next stage, the master cuts two identical pieces of strip 40 mm wide, in which holes must be drilled at the edges.

After this, the plates need to be welded to the main structure - through the drilled holes, the vise will be attached to the table using self-tapping screws (or it is possible on bolts with nuts). Then it will be necessary to grind and paint the homemade product.

For details on how to make simple table vice from an old manual jack, we recommend that you look in the video on the site.