In this review, the author shows how to make a universal puller, with which you can easily remove the ball bearings, steering tips and other components of the car.

The main advantage of this device is ease of manufacture and affordable cost. Having made such a device with your own hands, you will save about $ 20. At the same time, a home-made puller will also last longer.

In this case, the author uses a piece of the channel and a piece of the corner. You will also need large bolts with nuts (for example, from the wheel of a truck).

The main stages of work

First of all, you need to clean the channel and corner from rust and old paint. Then in the channel it is necessary to cut out part of the shelves with a grinder.

Similarly, you need to do it with a corner, but first you need to weld a side wall to it to get a channel. Ideally, use two channels of different sizes so that one fits into the other.

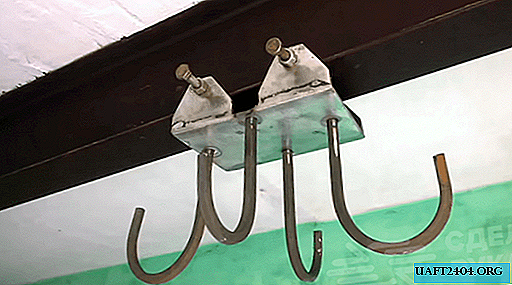

Then in the channel you will need to drill two holes, and then weld two nuts. Two holes also need to be drilled in the second workpiece, but no nuts need to be welded.

At the last stage, it remains only to make a cut in the channel, and then you can start assembling the device.

You can watch more details on how to make a universal puller for a motorist with your own hands in this video.