Homemade reusable beacons for bulk floors are useful in cases where it is impossible to drill holes in the base. For example, if a warm floor is laid under the base.

Making reusable lighthouses is quite simple - every master or person who has encountered construction work will cope with this task.

The author makes the base of the lighthouses from plywood 20 mm thick. The legs and the central rod can be made of welding electrodes.

As for the electrodes, for the manufacture of reusable beacons it is better to use those that are no longer suitable for welding.

Lighthouse manufacturing process

With the help of a circular saw on wood from a piece of plywood, it will be necessary to cut circles of a suitable diameter.

Further, in each of the blanks (the base of the lighthouse), it will be necessary to drill four holes.

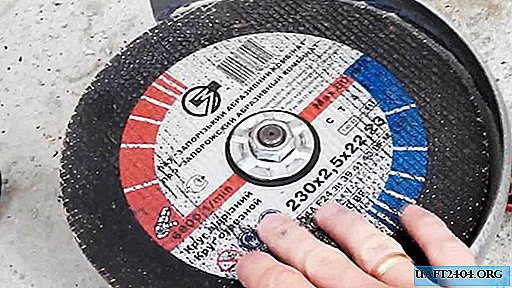

At the next stage, beat off the coating from the electrodes. Then we connect them using masking tape, make markings and cut them off with the help of a grinder or a cutting machine of the desired length.

See also: homemade metal cutting machine based on angle grinder.

Then you can proceed with the assembly of lighthouses. Everything is simple here - we insert the legs and the central bar into the drilled holes.

The legs of the lighthouse are 10 cm long and the central rod 22 cm long. The plywood base can be painted so that it can be clearly seen.

For details on how to make reusable beacons for bulk floors with your own hands, see the video.