Share

Pin

Tweet

Send

Share

Send

Hammer rivets An alternative to welding or threaded connections. To keep them secure, you need to choose them correctly. Standard rivets are not always suitable, so sometimes it is preferable to do them yourself. To do this, there is a special rivet block, which can be made in a garage or workshop. It allows you to create different length and diameter rivets of high quality.

Materials and Tools

To make a block will be used:

- steel plate with a thickness of 1 cm or more;

- 2 bolts with nuts;

- oil;

- a set of drills for metal;

- grinder with a cutting wheel;

- drill or drilling machine;

- vise;

- grinding machine.

Block assembly process

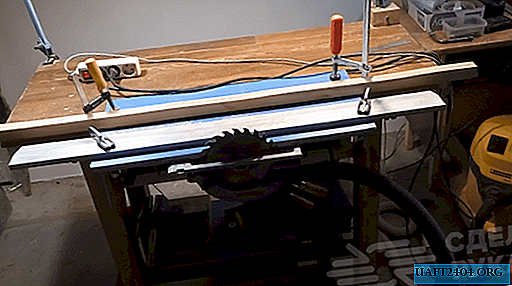

An old railway lining will be used as the basis for the block. She is very thick, so it fits perfectly. The smooth side of the slab must be sanded. Since steel is good, even on a machine it is difficult to do this for a long time.

Next, the grinder needs to cut the embossed edges of the lining. The central workpiece is cut along another 2 equal halves. They need to be folded in half, with smooth sides inward. Aligning the 3 sides of the plates, they are clamped with a clamp or vise.

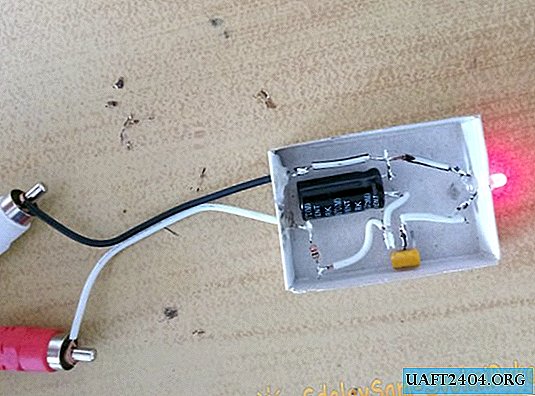

Folded workpieces are drilled to pull them off with a pair of bolts. The drill is heated, so you need to periodically add oil and sometimes stop to cool. Having made two holes, the plates are tightly attracted by bolts.

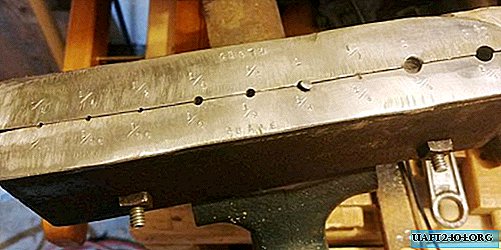

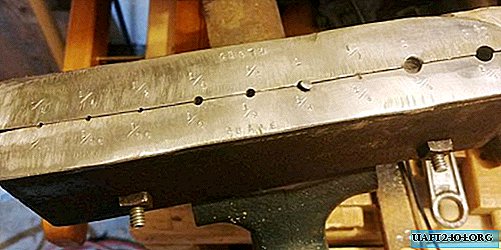

Putting the folded block on the end, with the long straight side up, make holes for rivets. You need to drill in the center at the junction of the plates. For this, drills of the diameter that rivets are needed are used. The depth of the holes will correspond to the length of the rivets. During drilling, it will be necessary to periodically tighten the tightening of the plates, since the thread of the bolts is released from vibration.

Having made the required number of templates for riveting, the block should be disassembled to clean from chips. Having assembled it back, you need to grind the end face with holes, having achieved one plane of the folded plates.

How to use the unit

A rod of mild steel, brass or copper is inserted into the hole for the rivet of the block. Its thickness should correspond to the diameter of the template. Next, the rod is cut slightly above the surface of the block. The length of the protruding tail should be 1.5 bar diameters. Having rested the block in the anvil or the deck, it is necessary to beat with a hammer with a rounded striker on the rivet blank. Her soft metal is deformed, forming a hat. The finished rivet falls out when loosening the bolts between the plates. If desired, the engraver can sign the diameters of the holes on the block.

Original article in English

Share

Pin

Tweet

Send

Share

Send