A master class on how to make a powerful, low-voltage water pump for various needs. For example, pump out a barrel of water for watering plants, etc. The pump works perfectly on a 12 V battery, which is its primary advantage.

Will need

- The 775 electric motor is the first thing you need. It can be bought on Ali Express at the link. Or find a similar one.

- Fitting for PVC pipes. The pump casing will be made of it.

Making a water pump

We take an adapter with a diameter of 50 mm to 32 mm.

And a plug for 50 mm pipe.

In the plug we place the holes for the engine: two for the mounting screws, one for the shaft.

We drill and clean from burrs.

Now you need to cut off the lower part. Mark a straight line by rotating the plug.

Saw off with a hacksaw. Using sandpaper, smooth the surface and get rid of burrs.

We also cut off the skirt of the adapter in the same way.

Combine the adapter with a plug to check the evenness of the surfaces.

We take a small piece of PVC pipe 20 mm in diameter and cut it at an angle of about 45 degrees. Next, you need to create a rounded surface of the trimmed edge. To do this, wrap the adapter with sandpaper and grind the edge of the tube until a circle shape is obtained.

In the adapter we make a hole for the tube.

Glue the tube into the hole using epoxy-based glue.

Take a disposable syringe and check how tightly it fits on the motor shaft. If it’s tight, then this is normal, so we need it.

Cut off the tip of the syringe.

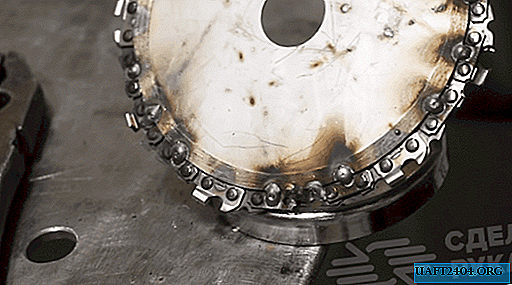

To make the impeller, it is necessary to cut a square from aluminum. Make a hole in it so that the skirt of the syringe puts on tight.

Mark the square into 9 parts.

Draw the diagonals in squares through the cage. See photo.

Cut corners with scissors for metal.

We bend the squares. See photo:

From an unnecessary camera from a bicycle or car, we cut the gasket under the engine.

We take the motor with screws.

We put on the gasket, put on the plug and fix it all with screws.

Then we put the cut-off pipette from the syringe with the skirt to the motor.

Next we put on the impeller. Everything should sit very tight. It will not be superfluous to glue everything with glue on an epoxy basis.

From the pipe 50 mm in diameter we cut a ring, approximately 10 mm wide. Insert half into the adapter. That part that is visible through the hole is removed.

Putting the pump together.

Glue the joint with hot glue.

We put a corner fitting on top of the tube.

And we glue another adapter into the adapter from a diameter of 32 mm to 20 mm. We fix on hot glue.

We insert the tube. It will be a water intake.

The time has come for testing. For reliability, you can fix the motor on the board by tying it with a metal clamp.

We will connect the system to a voltage of 12 V. We lower the intake pipe into a container of water. We apply voltage and the pump is running.

The jet is thrown about a meter.

Where and how to use a similar design is up to you. Bye everyone, see you soon!